America's Forgotten Manufacturing Hubs

The rumble of assembly lines creates the soundtrack for communities across America. Behind every vehicle lies a birthplace. These manufacturing hubs write economic stories that stretch far beyond their factory walls. Here are some legacy plants that continue traditions while newcomers redefine automotive production.

1. Toledo, Ohio

Mud-splattered Jeep Wranglers conquer off-road trails worldwide, but they're made in Toledo's sprawling 3.6-million-square-foot complex. The city's automotive legacy stretches back to John North Willys, who established operations in the early 1900s. Nearly 6,000 workers keep production rolling at this Stellantis-owned facility.

Part of Toledo Jeep Plant to temporarily shut down to 'retool the plant for a new model' by WTOL11

Part of Toledo Jeep Plant to temporarily shut down to 'retool the plant for a new model' by WTOL11

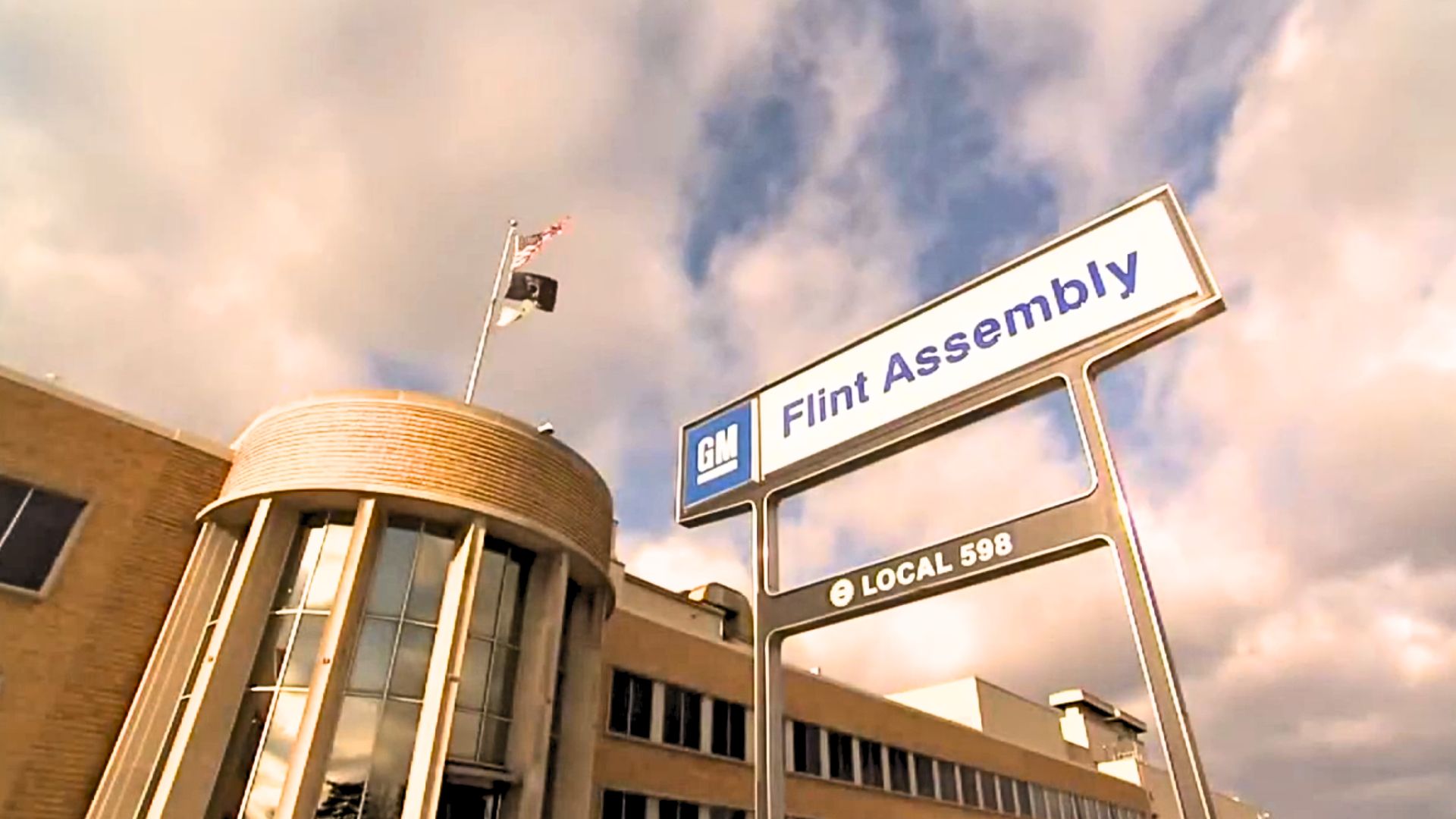

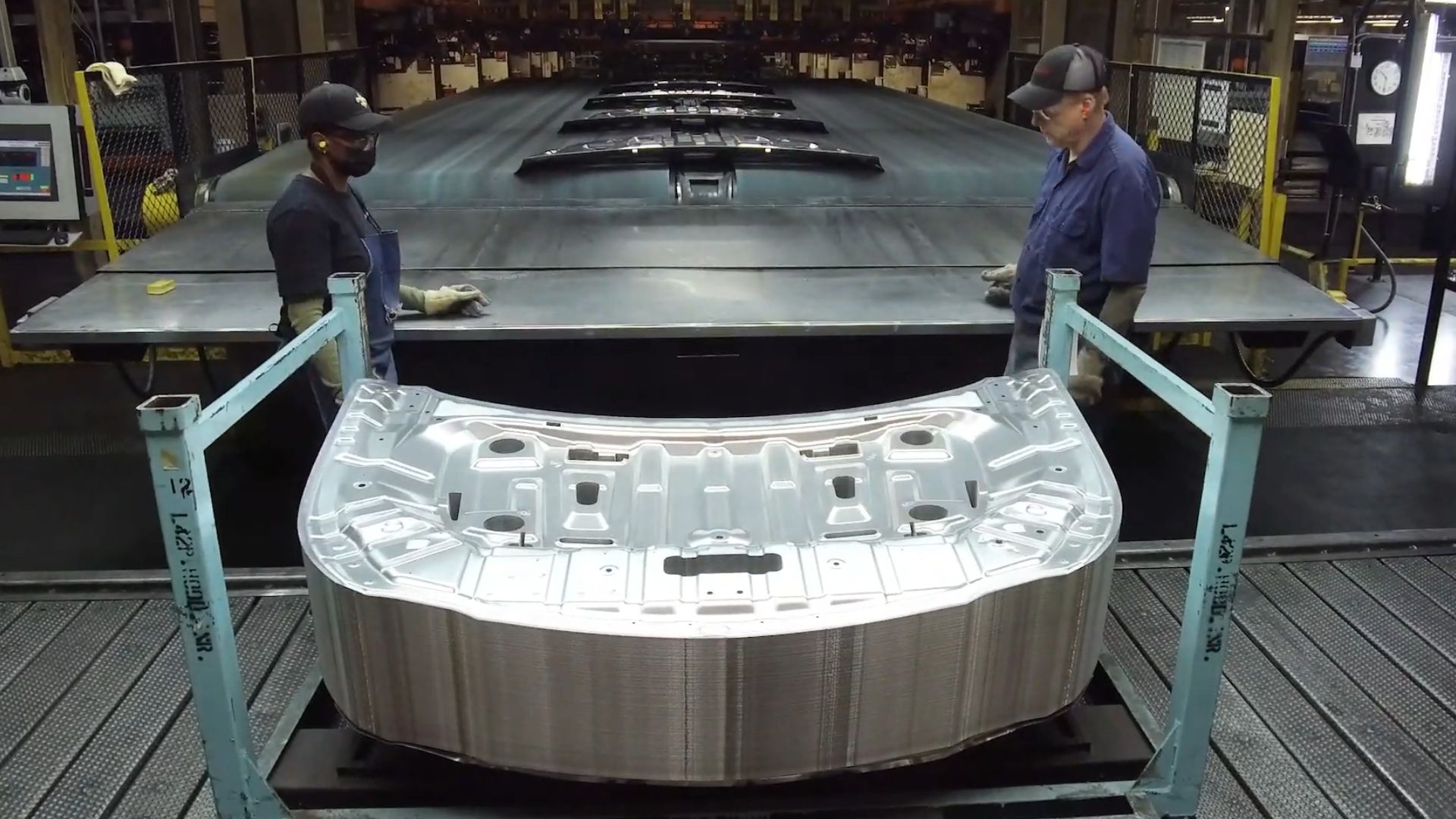

2. Flint, Michigan

Considered the birthplace of General Motors in 1908, this historic Michigan city claims the automotive industry's very soul. William "Billy" Durant founded his manufacturing empire here. The city's Flint Assembly produces heavy-duty Chevrolet Silverado and GMC Sierra pickups on its campus.

3. Louisville, Kentucky

Every 58 seconds, another gleaming Ford truck emerges complete from Louisville's massive Kentucky Truck Plant. The establishment is around 6 million square feet, equivalent to 102 football fields, making it Ford's largest truck manufacturing operation. Since 1969, it has been the birthplace of America's workhorse vehicles.

Ford to spend $700 million on Kentucky Truck Plant, add 500 jobs by WDRB News - Official

Ford to spend $700 million on Kentucky Truck Plant, add 500 jobs by WDRB News - Official

4. Spartanburg, South Carolina

Among South Carolina's rolling hills, approximately 1,500 BMW vehicles roll off assembly lines daily, with a remarkable 70% destined for international markets. The German automaker shocked industry experts by choosing this location in 1992. Before BMW arrived, agriculture dominated the local economy.

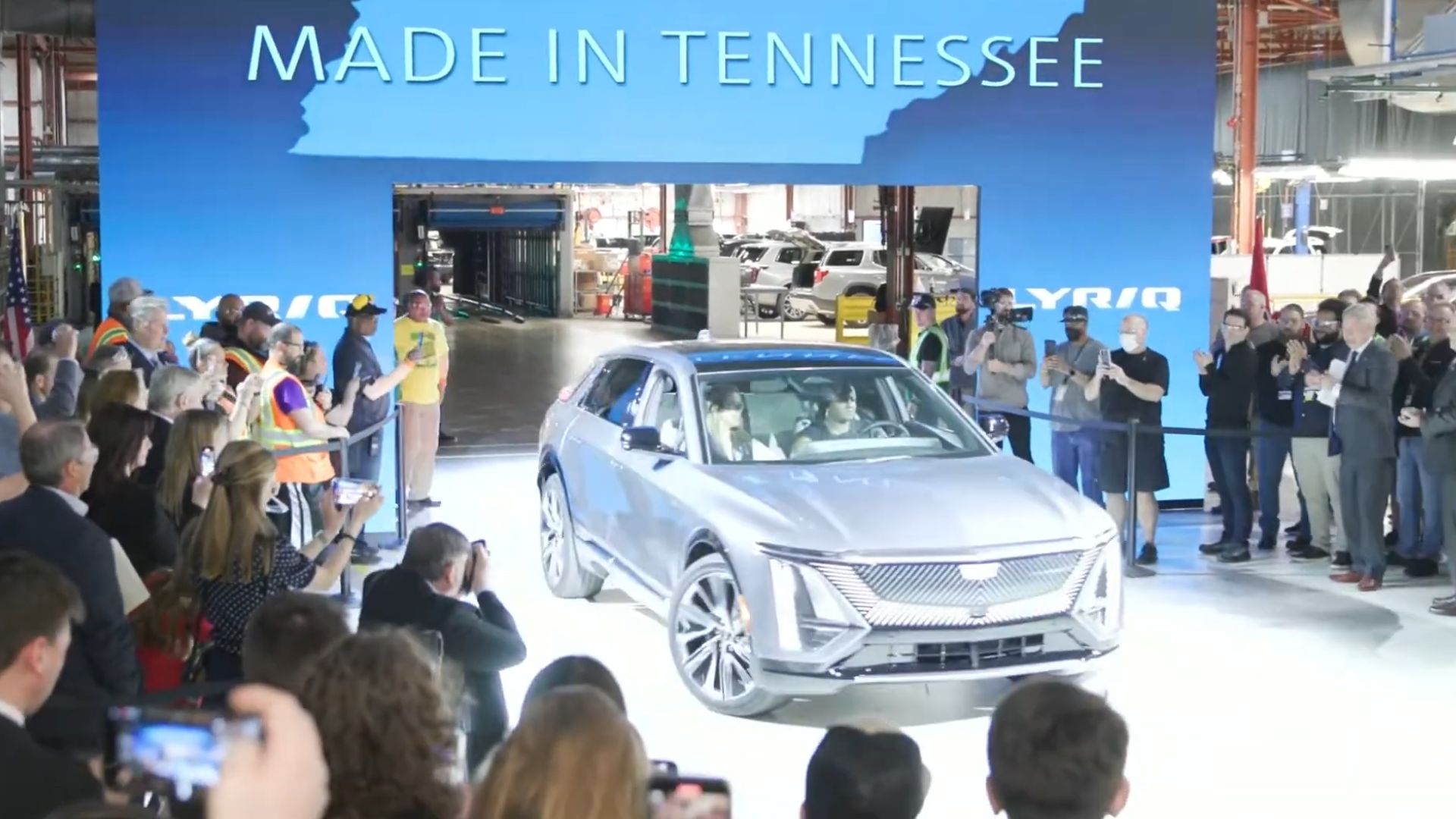

5. Spring Hill, Tennessee

What started in 1990 as America's automotive manufacturing revolution has evolved over three decades. The plant's construction represents the largest single building project in Tennessee's history. The remnants of Saturn's "different kind of car company" philosophy still echo in Spring Hill's GM facility.

GM Launches All-Electric Cadillac LYRIQ in Spring Hill, TN by TNECD

GM Launches All-Electric Cadillac LYRIQ in Spring Hill, TN by TNECD

6. Georgetown, Kentucky

This plant diverts 100% of waste from landfills while producing over 550,000 vehicles yearly. Toyota's first wholly-owned American plant, which opened in 1988, changed Kentucky's manufacturing scenario. Industry experts initially questioned Toyota's decision to build in a region without an automotive manufacturing tradition.

Censusdata at English Wikipedia on Wikimedia

Censusdata at English Wikipedia on Wikimedia

7. Fremont, California

Silicon Valley's influence materializes in Tesla's Fremont factory. This facility's walls witnessed automotive history long before Elon Musk's arrival. It previously housed NUMMI, the incredible GM-Toyota partnership that operated from 1984 to 2010. Tesla's acquisition of this shuttered plant symbolized American manufacturing's rebirth.

8. Marysville, Ohio

Cornfields gave way to car production when Honda broke ground in Ohio's heartland. The Japanese company decided to build engines here in 1982. Honda achieved zero-waste-to-landfill status while operating 2.2 million square feet of production space. This place has produced over 15 million vehicles.

Wiki Historian N OH (talk) on Wikimedia

Wiki Historian N OH (talk) on Wikimedia

9. Chattanooga, Tennessee

Platinum environmental certification, the first for any automotive factory globally, distinguishes Volkswagen's Tennessee facility. The German automaker selected this location in 2008 after evaluating sites nationwide, ultimately investing over $1 billion. Around 4,000 employees now produce the Atlas SUV and electric ID.4 here.

10. Canton, Mississippi

Raw steel turns into gleaming Nissan vehicles inside Canton's grand 4.7-million-square-foot area. This installation spans nearly 1,200 acres of what was once rural Mississippi farmland. Economic transformation followed Nissan's 2003 arrival in central Mississippi, where manufacturing jobs were previously scarce.

11. Lansing, Michigan

Ransom E. Olds constructed his first automobile here in 1897, establishing Lansing's automotive DNA decades before GM's current operations. The city demonstrated extraordinary production resilience by securing a new General Motors investment when older facilities closed. Lansing's Grand River Assembly plant opened in 2001.

12. West Point, Georgia

Quiet farmland changed overnight when Kia broke ground on its $1.2 billion production yard in 2009. Technical colleges throughout the region developed specialized training programs to support this automotive workforce. The Telluride, Sorento, and K5 models claim West Point as their birthplace.

13. Montgomery, Alabama

The South Korean automaker has built more than 5 million vehicles in this factory after selecting Montgomery from among 250 competing locations nationwide. Around 3,000 team members orchestrate the daily manufacturing ballet, having 3.4 million square feet of production space.

Carol M. Highsmith on Wikimedia

Carol M. Highsmith on Wikimedia

14. Arlington, Texas

Wind energy powers 100% of operations at GM's exclusive full-size SUV plant, where work continues around the clock. The location's evolution since 1954 mirrors American automotive preferences. Texas-sized production volumes exceed 1,200 vehicles daily within this 5.75-million-square-foot complex.

Arlington GM assembly plant not among first round of UAW strikes by CBS TEXAS

Arlington GM assembly plant not among first round of UAW strikes by CBS TEXAS

15. Smyrna, Tennessee

Nissan made the pioneering 1983 decision to establish America's first Japanese auto assembly plant. Six models rise from 640 acres of production space, including the popular Rogue, Pathfinder, and all-electric LEAF. Ignited by Smyrna's success, it has grown to become the state's largest manufacturing employer.

16. San Antonio, Texas

Exclusively, pickup trucks come from the only Toyota facility worldwide dedicated solely to truck production. Rainwater harvesting systems collect over 1.9 million gallons yearly to support these processes within the environmentally innovative operation. Toyota's 2006 arrival created an instant automotive sector in San Antonio.

Team Toyota: Athletes Visit Toyota Motor Manufacturing Texas in San Antonio | Toyota by Toyota USA

Team Toyota: Athletes Visit Toyota Motor Manufacturing Texas in San Antonio | Toyota by Toyota USA

17. Tuscaloosa, Alabama

Luxury vehicle production was uncharted territory for Alabama until Mercedes-Benz began construction in 1993. From initially producing just the M-Class SUV, operations expanded to include GLE, GLS, and electric EQE SUV models. Since it all began, over 4 million vehicles have proudly carried "Made in Alabama" credentials.

Carol M. Highsmith on Wikimedia

Carol M. Highsmith on Wikimedia

18. Blue Springs, Mississippi

World-famous reliability comes standard from Toyota's newest assembly area, opened following a $1.2 billion investment in 2011. This factory focuses exclusively on the Corolla, holding the distinction of producing the world's best-selling automotive nameplate. Zero waste reaches landfills from this environmentally conscious operation.

The “Toyota Experience” in Blue Springs,MS#toyota#Corolla by GloBeesTravels

The “Toyota Experience” in Blue Springs,MS#toyota#Corolla by GloBeesTravels

19. Normal, Illinois

Rebirth through electrification describes this establishment’s journey from an abandoned Mitsubishi plant to an innovative EV production center. All thanks to Rivian's 2017 acquisition and subsequent $1.5 billion investment. Its history includes three decades of producing Mitsubishi vehicles until operations ceased in 2015.

A Tour of the Rivian Plant | Go behind the scenes with founder RJ Scaringe by Rivian

A Tour of the Rivian Plant | Go behind the scenes with founder RJ Scaringe by Rivian

20. Wentzville, Missouri

Strategic central location makes this 5.1-million-square-foot GM installation ideal for nationwide distribution of its commercial-focused vehicles. Wentzville has specialized in vehicles built for work. It continues to produce the Chevrolet Colorado, GMC Canyon, and commercial vans across three shifts.

Layoffs at General Motors Wentzville plant affects 1,200 by FOX 2 St. Louis

Layoffs at General Motors Wentzville plant affects 1,200 by FOX 2 St. Louis