Factory Floor 4.0: AI and Smart Tech Transform Vehicle Production

The automotive factory floor doesn't look like it used to. Walk into Hyundai's new Georgia facility or Xiaomi's smartphone plant in China and you'll see robots working alongside humans, and AI systems predicting equipment failures before they happen. Manufacturers implementing smart factory initiatives are seeing annual productivity gains between 2% and 20%, saving millions in production costs.

Fixing Problems That Haven't Happened Yet

Equipment breaks down. It always has and always will. What's different now is that AI uses sensors to analyze vibration patterns, temperature fluctuations, acoustic signatures, and electrical consumption to predict failures before they occur. Instead of waiting for a machine to die during production or maintaining everything on fixed schedules regardless of actual condition, factories now service equipment precisely when the data indicates it's needed.

The business case is straightforward. Unplanned downtime on an automotive assembly line can cost $22,000 per minute when you factor in lost production, labor standing idle, and the ripple effects through the supply chain. As a result, Volkswagen has committed €1 billion by 2030 to AI-related industrial technologies, targeting €4 billion in savings by 2035. This commitment supports over 1,200 AI applications across production, connecting over 40 sites to optimize processes, energy use, and costs.

When Machines Work Alongside Humans

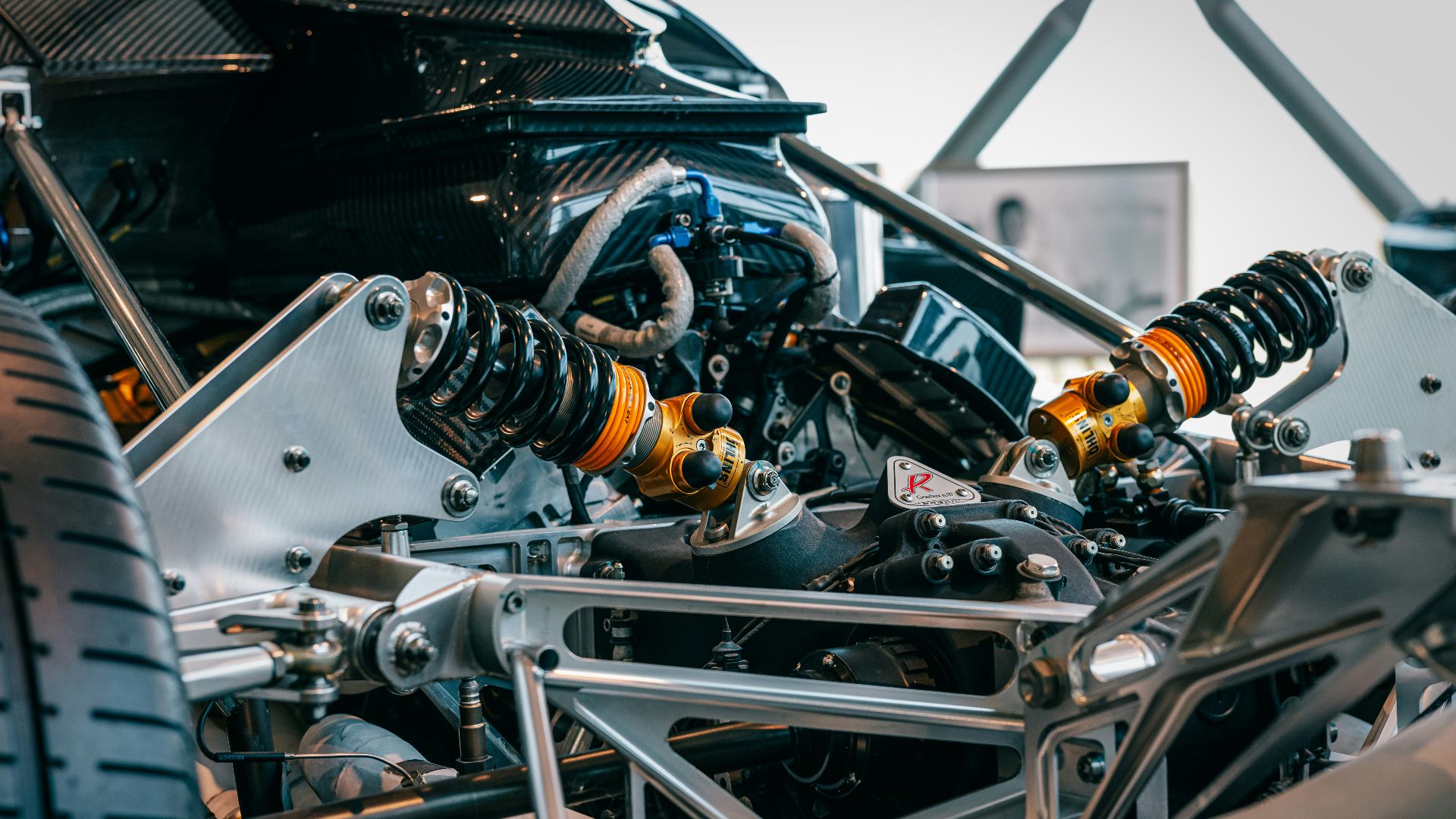

ThisisEngineering on UnsplashTraditional industrial robots lived in cages as safety regulations required physical barriers because these machines moved fast and couldn't distinguish between a car door and a human arm. AI-enabled “cobots” work alongside human workers, using force-limiting sensors to operate safely without safety cages.

ThisisEngineering on UnsplashTraditional industrial robots lived in cages as safety regulations required physical barriers because these machines moved fast and couldn't distinguish between a car door and a human arm. AI-enabled “cobots” work alongside human workers, using force-limiting sensors to operate safely without safety cages.

Back in 2021, Volkswagen introduced cobots to their assembly plants in Mexico to support its workforce, measure gap precision, and help with final inspection checks. In the Puebla plant, a worker assisted by a cobot can accurately measure 26 checkpoints in less than a minute.

Hyundai's new Georgia facility uses AI vision systems to verify component assemblies, guide positioning for automatic loading, and detect microscopic holes or cracks in panels. Unmanned transport vehicles carry pallets between stations and handle inventory management.

Meanwhile, human workers oversee the process, intervene when needed, and focus on tasks requiring creativity or complex judgment.

Testing Factory Changes Without Touching the Factory

Digital twins are virtual replicas of physical factories that enable engineers to simulate production changes, new product introductions, and process optimizations before implementing anything physically.

Empowered with this digital twin, an automotive engineer can observe precise virtual 3D models of equipment and manipulate them to see it from all angles, enabling them to identify any design flaws before they go into mass production. The savings from catching a design flaw in simulation versus catching it after tooling up for production can easily reach millions of dollars.

Seeing What Humans Can't

Hyundai Motor Group on Unsplash

Hyundai Motor Group on Unsplash

Quality control has always been labor-intensive and imperfect. Human inspectors get tired and miss defects. Random statistical sampling means some bad parts slip through. On the other hand, computer vision systems inspect products at speeds and accuracy levels impossible for human inspectors.

The systems work by training neural networks on thousands of images showing both acceptable and defective parts. The AI learns what "good" looks like across infinite variations in lighting, angle, and positioning. Once trained, it examines every single component at production speed, flagging anomalies that human eyes would never catch.

Every Machine Becomes a Data Source

The Industrial Internet of Things on the production line refers to interconnected sensors and other devices that can communicate with each other and exchange data in real time. Every piece of equipment on the factory floor generates continuous streams of data about its operation, health, and output.

That data feeds into centralized systems that orchestrate the entire production process. When a machine detects an anomaly, it can automatically adjust operating parameters, reroute work to backup equipment, or alert human supervisors for intervention.

Deloitte's 2025 survey of 600 manufacturing executives reveals a sector in transformation: 46% prioritize process automation, 41% are investing in factory automation hardware, and 60% anticipate increased revenues from smart manufacturing initiatives. These aren't pilot projects anymore; they're production deployments delivering measurable value and competitive advantages that compound over time.