You've seen it on the road—a 1990s Toyota Camry with 300,000 miles, still running like it rolled off the factory floor yesterday. Meanwhile, your neighbor's European luxury sedan needs another $2,000 repair after just 80,000 miles. What gives? Japanese automakers have earned their reputation for building bulletproof vehicles, and it's not just marketing hype.

There's actual engineering philosophy and manufacturing genius behind why a Honda Civic laughs in the face of odometers while other cars are headed to the junkyard.

Perfection Through Tiny Improvements

Japanese reliability didn't happen by accident—it's baked into the manufacturing DNA through a concept called "kaizen," which translates to "continuous improvement." After World War II, Japanese manufacturers adopted this philosophy religiously, making small, incremental improvements to every aspect of production.

Unlike Western automakers, who might redesign entire systems every few years, Japanese companies obsess over perfecting what already works. Toyota literally invented the famous "5 Whys" technique, where engineers ask "why" five times to get to the root cause of any problem. Found a defective part? Why did it fail? Because the metal is fatigued.

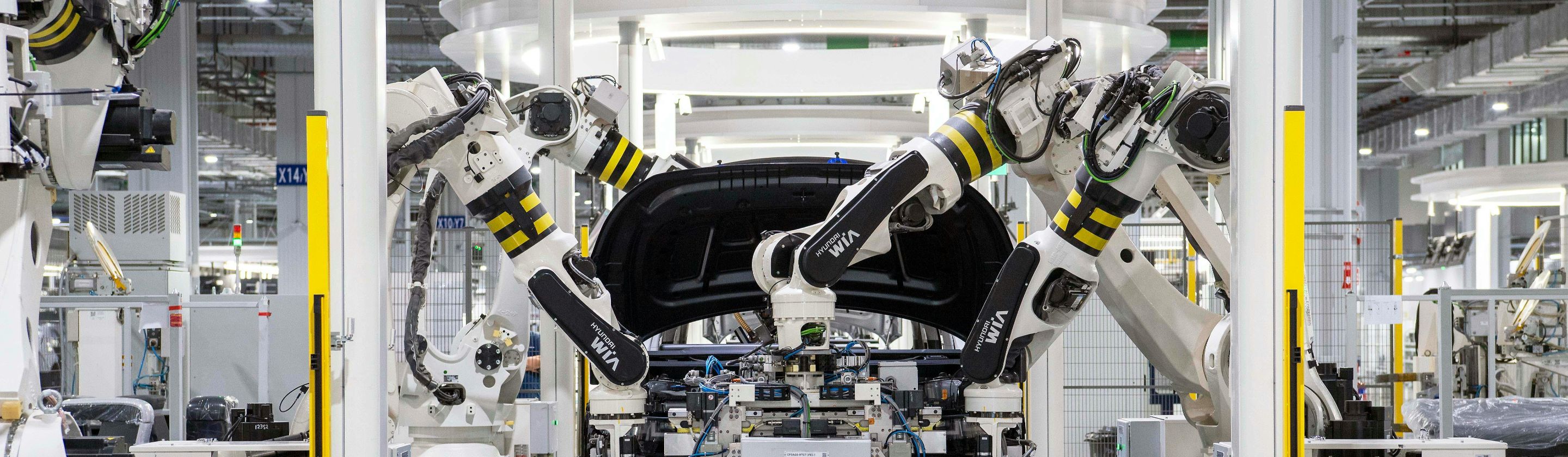

Why? Because the heat treatment was inconsistent. And so on. This relentless problem-solving culture means issues get fixed before they become endemic nightmares across entire production lines. The results speak volumes. Japanese automakers pioneered just-in-time manufacturing, where parts arrive exactly when needed, reducing inventory waste but demanding absolute precision from suppliers.

Every component must be perfect because there's no warehouse full of backups. This system forces quality control at every single step.

Engineered For The Long Game

Here's where Japanese cars diverge from their competitors: they're deliberately overengineered for longevity rather than peak performance. A German sports car might push boundaries with amazing tech, but Japanese engineers ask a different question: how can we make this run flawlessly for 20 years?

Take engine design. Japanese manufacturers typically use simpler, proven technologies with generous tolerances. Honda's naturally aspirated engines, for instance, operate well below their stress limits, meaning components wear slowly. They're not chasing the absolute maximum horsepower per liter; they're building motors that your grandkids could inherit.

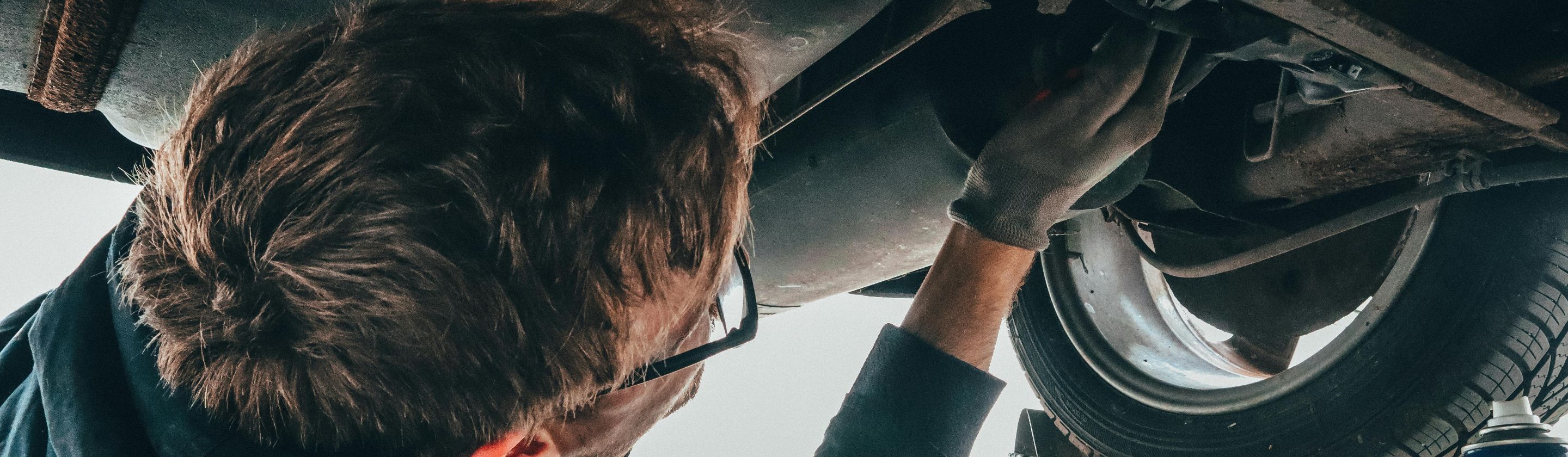

The parts selection matters too. Japanese automakers often stick with the same reliable suppliers for decades, building relationships that ensure consistent quality. They also design with maintenance in mind—oil filters in accessible spots, timing chains instead of belts that need replacement, and electrical systems that don't resemble spaghetti nightmares.

Testing Beyond Extremes

Before any Japanese car hits dealerships, it's been tortured in ways that would make other manufacturers wince. Toyota runs vehicles through Arizona deserts, Minnesota winters, and simulated decades of wear compressed into months of testing. They literally ship prototype cars to the world's worst roads to find breaking points.

Mazda's proving grounds include a "stone road" designed to shake cars apart. Nissan tests door hinges for 100,000 cycles, roughly 30 years of use. This obsessive testing culture catches problems before customers ever see them, which is why you'll find 25-year-old Accords still daily-driving with original transmissions.